Solid Fuel Fire Training Simulation System

Realistic flashover and backdraft training for professional firefighters

Modern firefighting demands experience under extreme conditions - but real-world fire incidents are becoming less frequent.

The Solid Fuel Fire Training Simulation System is designed to recreate realistic fire environments for professional firefighter training. By using real solid fuel combustion, the system enables safe, repeatable exposure to extreme fire behavior, supporting operational readiness and decision-making under stress.

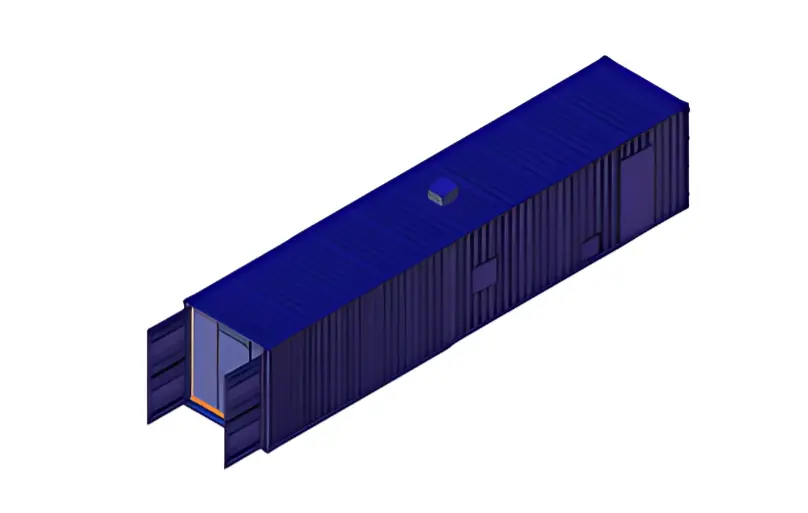

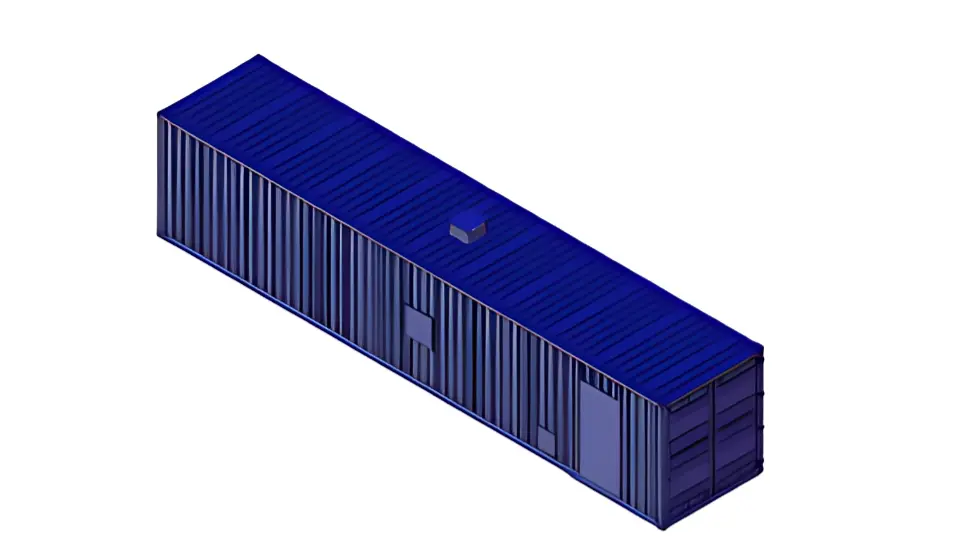

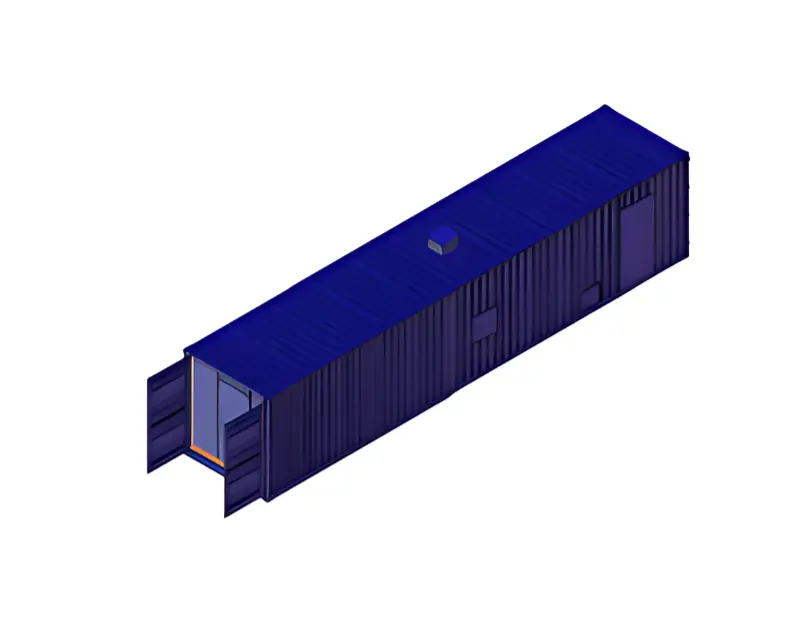

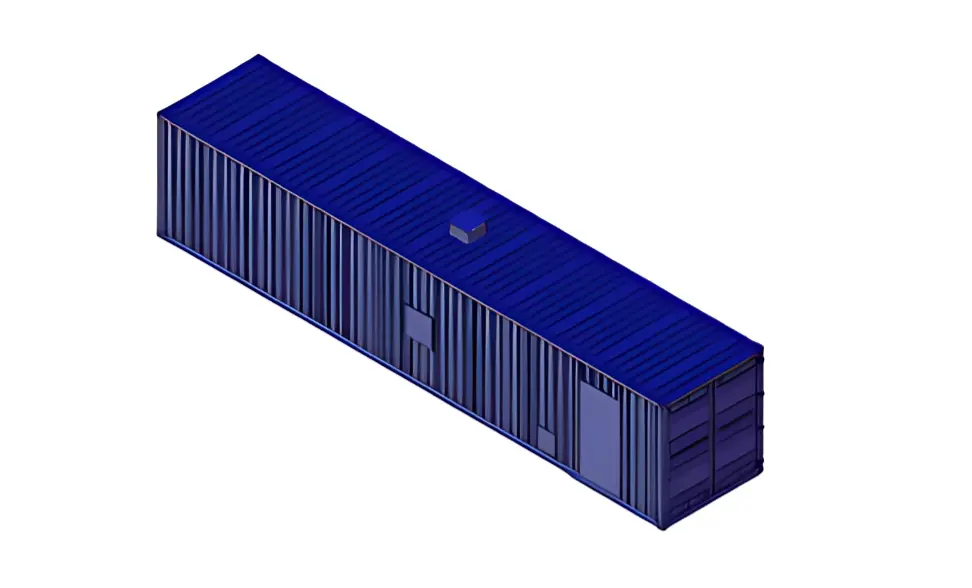

Single Module Solid Fuel Fire Training Simulation System

Realistic flashover and backdraft training for professional firefighters

Modern firefighting demands experience under extreme conditions -

but real-world fire incidents are becoming less frequent.

The Single Module Solid Fuel Fire Training Simulation System is designed to recreate realistic fire environments for professional firefighter training. By using real solid fuel combustion, the system enables safe, repeatable exposure to extreme fire behavior, supporting operational readiness and decision-making under stress.

Over recent decades, improvements in fire prevention and building safety have led to a significant reduction in major fire incidents.

While this represents a success in public safety, it has also reduced firefighters’ exposure to real operational fires -

particularly those involving extreme fire behavior.

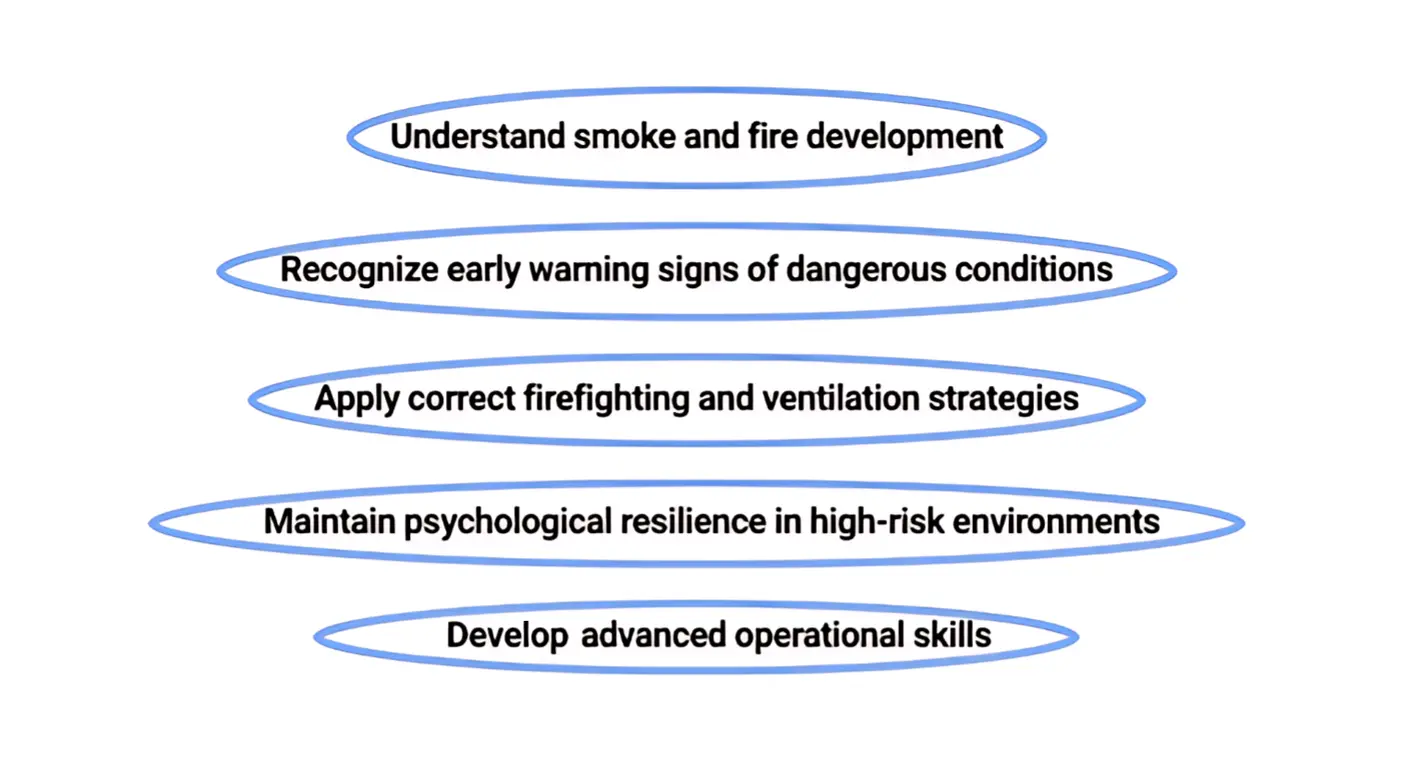

Hands-on experience with live fire dynamics remains essential to:

Why Realistic Fire Training Is Essential?

Over recent decades, improvements in fire prevention and building safety have led to a significant reduction in major fire incidents.

While this represents a success in public safety, it has also reduced firefighters’ exposure to real operational fires -

particularly those involving extreme fire behavior.

Why Realistic Fire Training Is Essential?

Hands-on experience with live fire dynamics remains essential to:

Understand smoke and fire developement

Recognize early warning signs of dangerous conditions

Apply correct firefighting and ventilation strategies

Maintain psychological resilience in high-risk environments

Develop advanced operational skills

Modern firefighter training increasingly relies on methodologies developed over the past decades, including live-fire approaches such as those originally introduced in Northern Europe

(“Swedish Rescue” approach).

These methods emphasize direct observation of fire and smoke behavior using real combustible materials.

Unlike artificial flame simulators, this system uses solid fuel combustion to generate authentic:

Modern firefighter training increasingly relies on methodologies developed over the past decades, including live-fire approaches such as those originally introduced in Northern Europe (“Swedish Rescue” approach).

These methods emphasize direct observation of fire and smoke behavior using real combustible materials.

Unlike artificial flame simulators, this system uses solid fuel combustion to generate authentic:

Flames and radiant heat

Dense smoke layers

Dynamic fire development in eclosed spaces

Extreme phenomena such as flashover and backdraft

Multi-Scenario Solid

Fuel Fire Training System

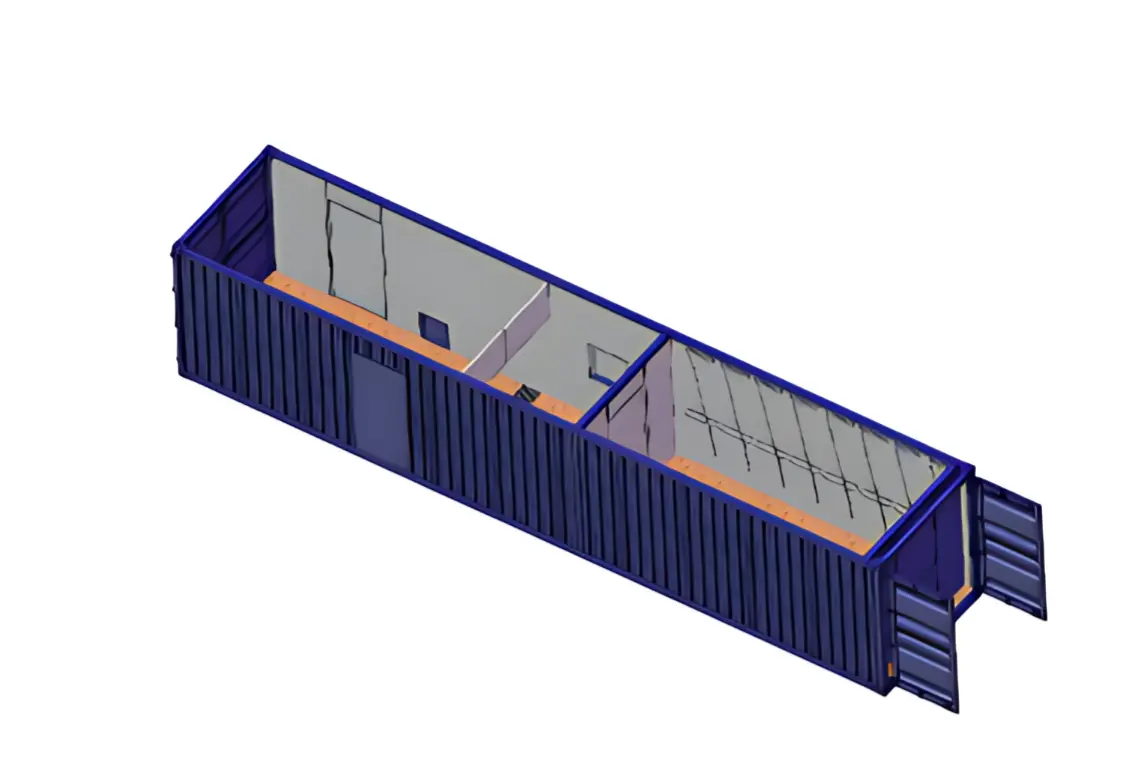

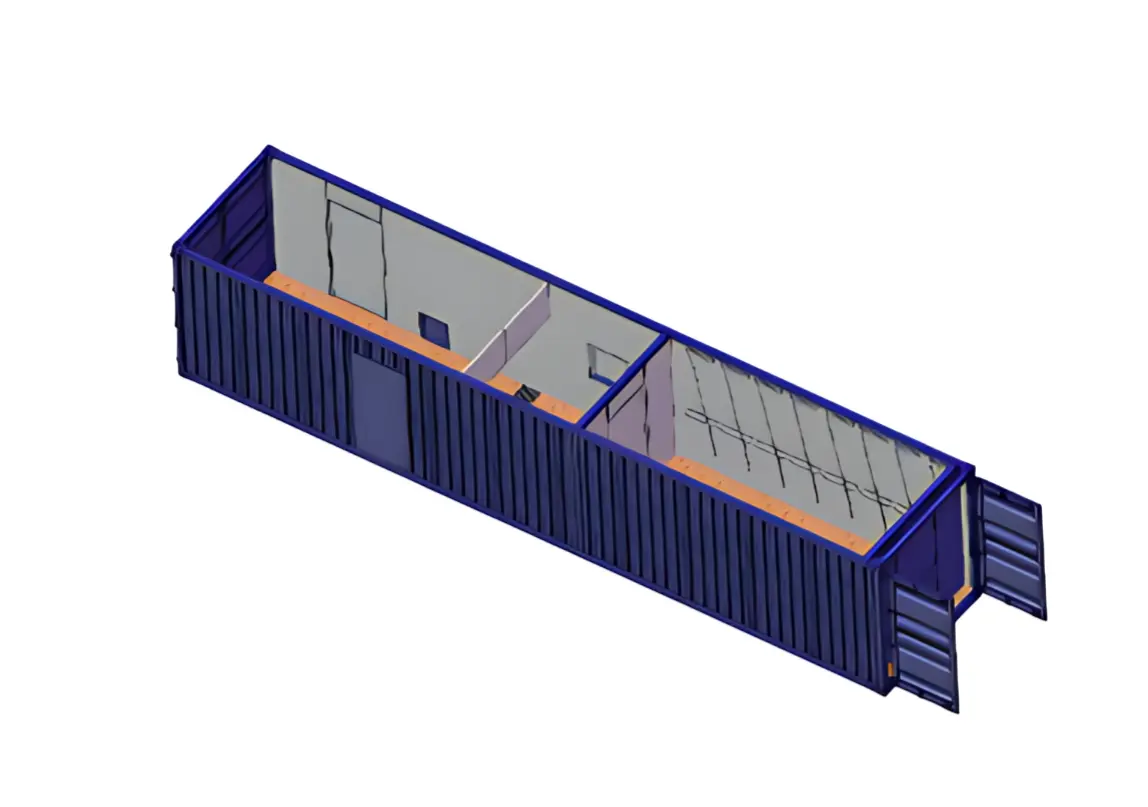

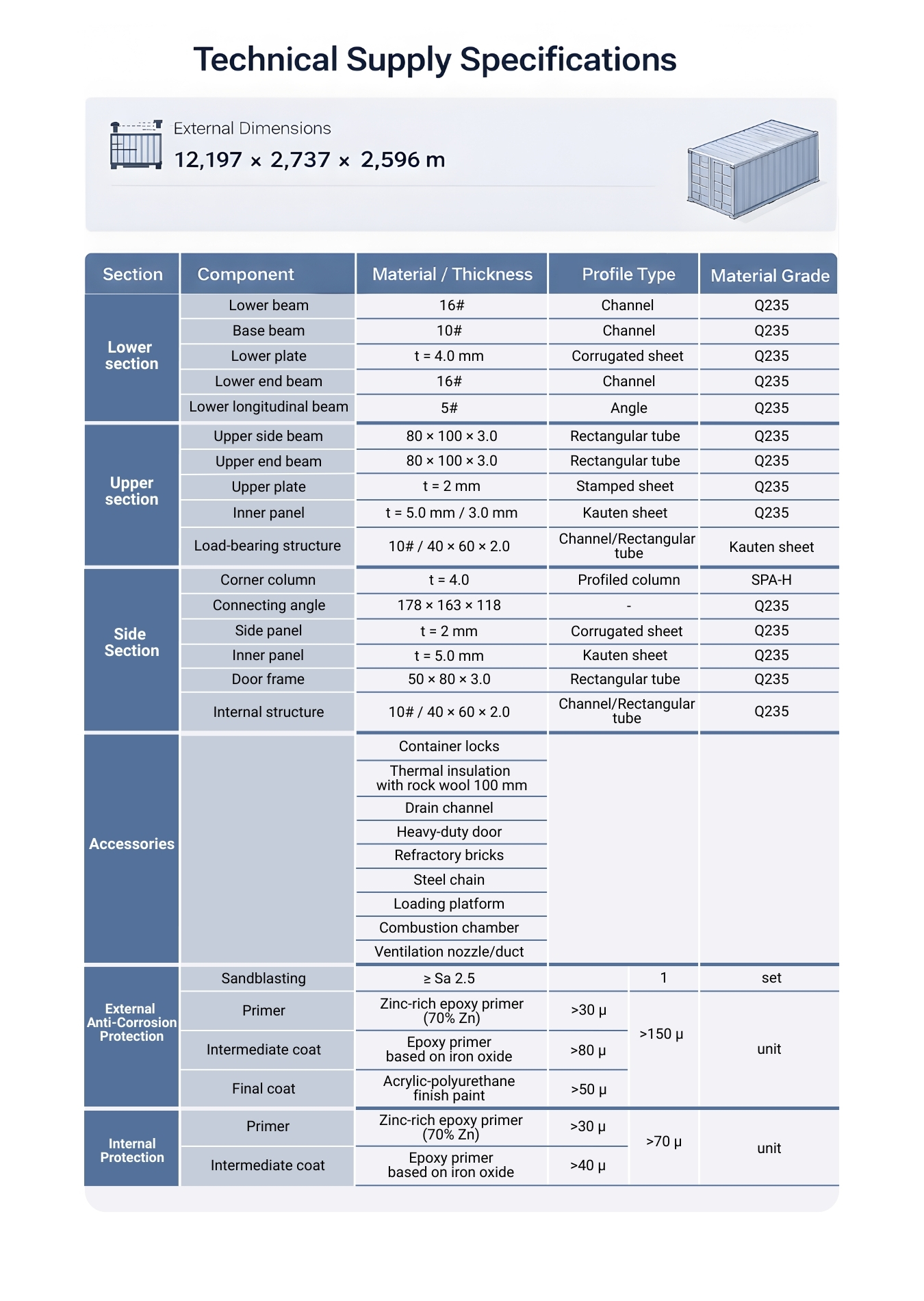

The Multi-Scenario Solid Fuel Fire Training System is a container-based installation designed to simulate realistic and extreme fire conditions for professional training purposes.

The Multi-Scenario Solid Fuel Fire Training System is a container-based installation designed to simulate realistic and extreme fire conditions for professional training purposes.

Multi-Scenario Solid Fuel Fire Training System

Flashover development and recognition

Backdraft ignition and prevention

High-temperature smoke environments

Confined-space fire behaviour

Side A

Side B

Upper and lower doors for backdraft

Wood fire combustion area

Back door of the observation area

Observation area and combustion

Side A

Side B

Upper and lower doors for backdraft

Wood fire combustion area

Back door of the observation area

Observation area and combustion

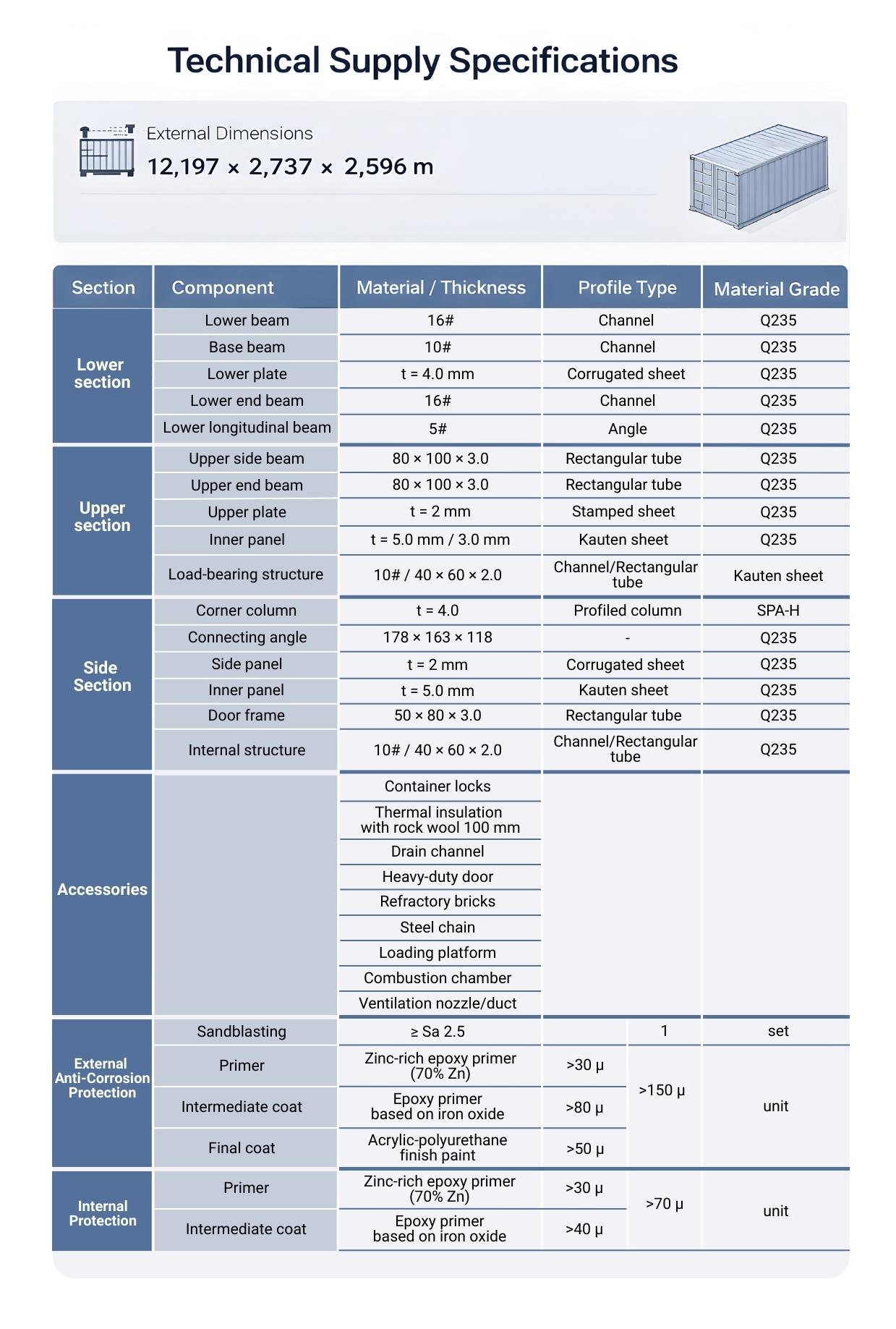

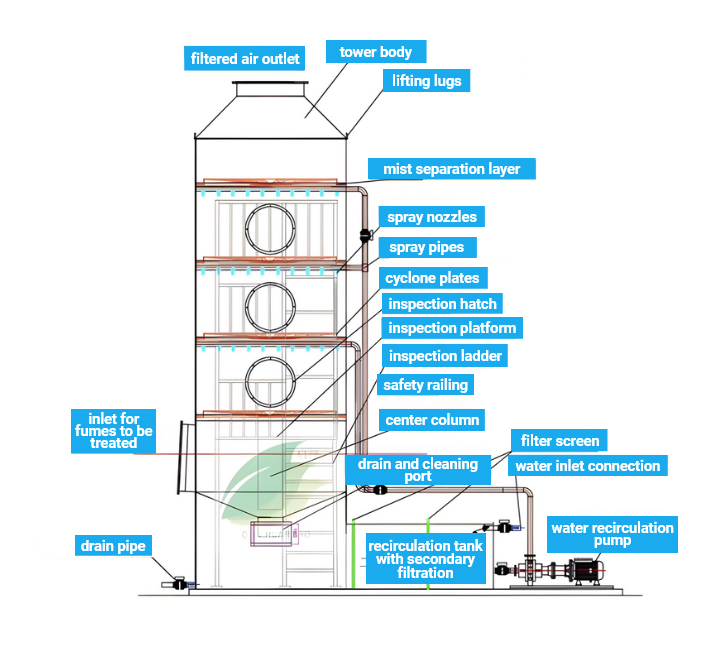

1. Main Duct – Airflow Capacity Q = 30,000 m³/h

2. Cyclone Plate Spray Tower – Airflow Capacity Q = 30,000 m³/h

Circulating Water Pump

- Quantity: 1 unit

- Type: Vertical centrifugal pump without mechanical seal

- Power: 3.75 kW

- Material: FRPP

- Power supply: Three-phase 380 V

- Head: 25 m

- Flow rate: 32 m³/h

Main Scrubber Tower Structure

- Tower diameter: 2000 mm

- Maximum overall height: 5400 mm

Cyclone plate structure includes:

- Two spray levels

- One mist separation stage

Material:

- Stainless steel 304, thickness 2.0 mm (±0.2)

Equipment pressure resistance:

- 700–800 Pa

Recirculating Water Tank

- Effective dimensions: 2500 × 2000 × 800 mm

- Material: Stainless steel 304

- Thickness: 2.0 mm (±0.2)

Anti-Clogging Spray Nozzles

- Model: DN25

- Quantity: 12 nozzles per level

- Levels: 2

- Total nozzles: 24 units

Function:

Designed to maximize gas–water contact area, ensuring:

- Coverage ≥ 170–250%

- Nozzle spacing ≤ 400 mm

This configuration significantly enhances purification efficiency and operational reliability.

3. Centrifugal Fan (with Variable Frequency Drive)

- Main duct diameter: 0.8 m

- Nominal air velocity: 18 m/s

- Airflow rate: 30,000 m³/h

Calculated air velocity:

Airflow 30,000 m³/h ÷ duct cross-section area = 16.58 m/s

Duct construction:

- Diameter: 800 mm

- Material: Galvanized steel sheet, thickness 1.0 mm (±0.2)

- All duct joints are fully sealed to ensure airtight operation and efficiency

- Airflow capacity: 30,000 m³/h

- Model: 4-72-8C

- Power: 18.5 kW

- Flow range: 17,674 – 32,771 m³/h

- Rotational speed: 1450 rpm

- Voltage: 380 V

- Pressure loss: 2187 – 1604 Pa

Chemical Filtration System

- Neutralization filtration technology

- Chemical tank material: PP

- Integrated automatic pH electrical control

- Dosing pump power: 250 W

- Carbon steel structural frame

1. Main Duct – Airflow Capacity Q = 30,000 m³/h

2. Cyclone Plate Spray Tower – Airflow Capacity Q = 30,000 m³/h

Circulating Water Pump

- Quantity: 1 unit

- Type: Vertical centrifugal pump without mechanical seal

- Power: 3.75 kW

- Material: FRPP

- Power supply: Three-phase 380 V

- Head: 25 m

- Flow rate: 32 m³/h

Main Scrubber Tower Structure

- Tower diameter: 2000 mm

- Maximum overall height: 5400 mm

Cyclone plate structure includes:

- Two spray levels

- One mist separation stage

Material:

- Stainless steel 304, thickness 2.0 mm (±0.2)

Equipment pressure resistance:

- 700–800 Pa

Recirculating Water Tank

- Effective dimensions: 2500 × 2000 × 800 mm

- Material: Stainless steel 304

- Thickness: 2.0 mm (±0.2)

Anti-Clogging Spray Nozzles

- Model: DN25

- Quantity: 12 nozzles per level

- Levels: 2

- Total nozzles: 24 units

Function:

Designed to maximize gas–water contact area, ensuring:

- Coverage ≥ 170–250%

- Nozzle spacing ≤ 400 mm

This configuration significantly enhances purification efficiency and operational reliability.

3. Centrifugal Fan (with Variable Frequency Drive)

- Main duct diameter: 0.8 m

- Nominal air velocity: 18 m/s

- Airflow rate: 30,000 m³/h

Calculated air velocity:

Airflow 30,000 m³/h ÷ duct cross-section area = 16.58 m/s

Duct construction:

- Diameter: 800 mm

- Material: Galvanized steel sheet, thickness 1.0 mm (±0.2)

- All duct joints are fully sealed to ensure airtight operation and efficiency

- Airflow capacity: 30,000 m³/h

- Model: 4-72-8C

- Power: 18.5 kW

- Flow range: 17,674 – 32,771 m³/h

- Rotational speed: 1450 rpm

- Voltage: 380 V

- Pressure loss: 2187 – 1604 Pa

Chemical Filtration System

- Neutralization filtration technology

- Chemical tank material: PP

- Integrated automatic pH electrical control

- Dosing pump power: 250 W

- Carbon steel structural frame